Use as part of closed-path eddy-covariance system

Overview

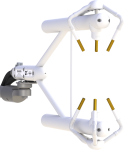

Campbell Scientific's EC155 closed-path analyzer incorporates vortex technology for reduced maintenance, an absolute pressure sensor in the sample cell for more accurate measurements, and a sample cell with improved corrosion protection. The EC155 can be combined with the CSAT3A sonic anemometer, as shown in the main image. The revised CSAT3A has a more aerodynamic and rigid design.

The EC155 is ordered as part of the CPEC200 system, which also includes the sample pump, datalogger, optional valve module, and optional scrub module to provide a zero air source. The EC155 with anemometer simultaneously measures absolute carbon dioxide and water vapor mixing ratio, sample cell temperature and pressure, and three-dimensional wind speed and sonic air temperature.

Read MoreBenefits and Features

- Vortex Intake (U.S. Pat. No. 9,217,692) greatly reduces maintenance frequency compared to traditional in-line filters

- Heated inlet increases protection against condensation

- More accurate pressure measurements with the new sample cell absolute pressure sensor

- Fully integrated, detachable intake

- Improved corrosion protection with stainless-steel sample cell

- Improved sonic temperature from more rigid CSAT3 geometry

- Stream-lined, aerodynamic CSAT3A mounting

- Slim aerodynamic shape with minimal wind distortion

- Analyzer, sample cell, and sonic anemometer measurements have matched bandwidths and are synchronized by a common set of electronics

- Low power consumption; suitable for solar power applications

- Low noise

- Small sample cell for excellent frequency response

- Integrated zero/span connection for simplified field zero/span

- Field rugged

- Field serviceable

- Factory calibrated over wide range of CO2, H2O, pressure and temperature in all combinations encountered in practice

- Extensive set of diagnostic parameters

- Fully compatible with Campbell Scientific data loggers; field setup, configuration, and field zero and span can be accomplished directly from the data logger

- Rain: innovative signal processing and transducer wicks considerably improve performance of the anemometer during precipitation events

Images

Similar Products

Detailed Description

The EC155 has the following outputs:

- Ux (m/s)*

- Uy (m/s)*

- Uz (m/s)*

- Sonic Temperature (°C)*

- Sonic Diagnostic*

- CO2 Mixing Ratio (µmol/mol)

- H2O Mixing Ratio (mmol/mol)

- Gas Analyzer Diagnostic

- Cell Temperature (°C)

- Cell Pressure (kPa)

- CO2 Signal Strength

- H2O Signal Strength

- Differential Pressure (kPa)

- Source Temperature (°C)

*Requires a CSAT3A Sonic Anemometer Head.

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Specifications

| Operating Temperature Range | -30° to +50°C |

| Operating Pressure | 70 to 106 kPa |

| Input Voltage Range | 10 to 16 Vdc |

| Power | 5 W (steady state and power up) at 25°C |

| Measurement Rate | 60 Hz |

| Output Bandwidth | 5, 10, 12.5, or 20 Hz (user-programmable) |

| Output Options | SDM, RS-485, USB, analog (CO2 and H2O only) |

| Auxiliary Inputs | Air temperature and pressure |

| EC100 Barometer Accuracy |

|

| Sample Intake/Sonic Volume Separation | 15.6 cm (6.1 in.) |

| Warranty | 3 years or 17,500 hours of operation (whichever comes first) |

| Cable Length | 3 m (10 ft) from EC155/CSAT3A to EC100 |

| Weight |

|

Gas Analyzer |

|

| Sample Cell Thermistor Accuracy | ± 0.15°C (-30° to +50°C) |

| Sample Cell Pressure Accuracy | ± 1.5 kPa (> 0°C ), increasing linearly to ±3.7 kPa at -30°C |

Gas Analyzer - CO2 Performance |

|

| Accuracy |

|

| Precision RMS (maximum) |

0.15 µmol/mol Nominal conditions for precision verification test: 25°C, 86 kPa, 400 μmol/mol CO2, 12°C dewpoint, and 20 Hz bandwidth. |

| Calibrated Range | 0 to 1,000 μmol/mol (0 to 3,000 µmol/mol available upon request.) |

| Zero Drift with Temperature (maximum) | ±0.3 μmol/mol/°C |

| Gain Drift with Temperature (maximum) | ±0.1% of reading/°C |

| Cross Sensitivity (maximum) | ±1.1 x 10-4 mol CO2 /mol H2O |

Gas Analyzer - H2O Performance |

|

| Accuracy |

|

| Precision RMS (maximum) |

0.006 mmol/mol Nominal conditions for precision verification test: 25°C, 86 kPa, 400 μmol/mol CO2, 12°C dewpoint, and 20 Hz bandwidth. |

| Calibrated Range | 0 to 72 mmol/mol (38°C dewpoint) |

| Zero Drift with Temperature (maximum) | ±0.05 mmol/mol/°C |

| Gain Drift with Temperature (maximum) | ±0.3% of reading/°C |

| Cross Sensitivity (maximum) | ±0.1 mol H2O/mol CO2 |

Sonic Anemometer - Accuracy |

|

| -NOTE- | The accuracy specification for the sonic anemometer is for wind speeds < 30 m s-1 and wind angles between ±170°. |

| Offset Error |

|

| Gain Error |

|

| Measurement Precision RMS |

|

Documents

Product Brochures

Manuals

Downloads

ECMon v.1.6 (10.7 MB) 29-03-2016

EC100-Series Support Software.

EC100 OS v.8.02 (560 KB) 14-10-2019

EC100 Operating System.

Watch the Video Tutorial: Updating the EC100 Operating System.

Device Configuration Utility v.2.32.01 (47.7 MB) 15-04-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

Frequently Asked Questions

Number of FAQs related to EC155: 4

Expand AllCollapse All

-

The molecular sieve has been demonstrated here by our engineering department to be effective at removing CO2 and H2O from the air sample. The change was made for two reasons:

- It was a safer alternative than using the previous chemicals.

- Increased shipping regulations for the chemicals limited the number of suppliers.

-

The molecular sieve is a non-hazardous material that can be shipped to any country.

-

The molecular sieve is a direct replacement for the old magnesium perchlorate bottles. The molecular sieve may be used for any Campbell Scientific analyzer that used the old bottles.

-

The bottles of sieve for drop-in replacement contain the pellets and a membrane on top. The membrane is necessary to keep the pellets contained while allowing gas to pass over the zeolite. The bottle has the same footprint as the old magnesium perchlorate bottles. The amount in each bottle is listed on the bottle. The amount of sieve needed for each analyzer is the following:

- The EC150 needs 22 g (drop-in bottle).

- The IRGASON® needs 22 g (drop-in bottle).

- The EC155 needs 22 g (drop-in bottle).

- The AP200 needs 500 g (refill).

- The 27423 needs 1000 g (refill).

- The 31022 needs 500 g (refill).