Overview

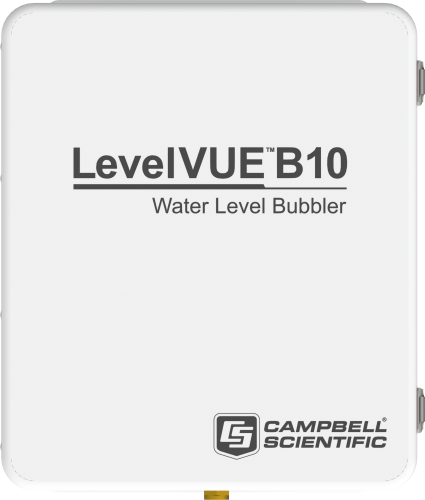

The LevelVue™B10 is a cost-effective, accurate, reliable solution for water-level measurements based on a non-submersible pressure transducer system. This type of sensor is a bubbler. Bubblers accurately measure the pressure it takes to create a continuous airflow in an airline submerged in water. The LevelVue B10 is designed for ease of use while providing long-term performance and accuracy. With a built-in keypad and display, you can complete your setup and site visit tasks using the LevelVue B10. The LevelVue B10 interfaces with data loggers or other controllers using SDI-12 or Modbus.

Read MoreBenefits and Features

- Low-power idle state for extended battery life

- Proprietary high-pressure/high-volume purge operation to prevent sediment buildup

- Simultaneous operation on the SDI-12 interface and Modbus interface

- Built-in keypad/display for full setup and maintenance operation

- Incorporated SDI-12 version 1.4 metadata commands for identification of data

- Standard cold temperature (-40°C) operation

- Proprietary air flow/bubble generation designed for years of trouble-free operation

Images

3D/CAD Files:

Detailed Description

The LevelVue B10 bubbler incorporates all the components needed to be a self-contained, pressurized air-supply system. This bubbler has an industrial air compressor (-40° to +80°C), large air tank (0.8 L), and other components that replace the need for pressurized air tanks and manual valves found in the older continuous gas flow systems. The LevelVue B10 meters the airflow to create a constant flow in the orifice line regardless of the water depth above the outlet. Precision sensors monitor the tank pressure and the line pressure to consistently maintain the same airflow. The precision sensor monitoring the pressure on the orifice line precisely detects the pressure required to push air through the line. This pressure value is directly related to water depth. Applying a simple conversion to the pressure value creates the value of water depth in feet, meters, or other units of measure.

Specifications

| Operating Temperature Range | -40° to +60°C |

| Storage Temperature Range | -40° to +80°C |

| Relative Humidity | 0 to 95% (non-condensing) |

| Accuracy | ≤ 0.02% of full-scale output (FSO) over temperature range |

| Sensor Overpressure Rating | 2 times the pressure |

| Memory | All settings and parameters are stored in non-volatile memory. |

| Real-Time Clock | Clock continues to operate with lithium battery, preserving the bubbler's time over power disconnects. |

| Long-Term Drift | 0.1% FS/6 months |

| Enclosure Material | Fiberglass |

| Enclosure Dimensions | 28.89 x 33.66 x 13.34 cm (11.375 x 13.25 x 5.25 in.) external |

| Enclosure Weight | 7.48 kg (16.5 lb) |

Sensor Resolution for Range |

|

| 0 to 10.54 m (34.6 ft) | ±2.1 mm (0.007 ft) for 0 to 15 PSI |

| 0 to 21 m (69.2 ft) | ±4.26 mm (0.014 ft) for 0 to 30 PSI |

| 0 to 35.16 m (115.35 ft) | ±7.11 mm (0.023 ft) for 0 to 50 PSI |

Airflow |

|

| Airflow Type | Microprocessor-controlled constant airflow over full pressure range and temperature |

| Bubble Rate |

|

| Manual Purge Operation | Immediate purge triggered via built-in keypad/display, SDI-12 command, or Modbus register |

| Purge Pressure | 30 to 90 PSI (user-programmable) |

| Purge Activation |

|

| Purge Sustain Time | 0 to 30 s (programmable) |

| Pressure Inlet | 1/8 in. female NPT |

| Orifice Line Outlet | 1/8 in. female NPT |

Power |

|

| Input Voltage Range | 11.5 to 16.5 V |

| Current |

|

| Power Protection | Power inputs are protected against surge, overvoltage, and reverse polarity connection of supply power up to 20 VDC. The internal air compressor is protected by the system level reverse polarity protection. |

| Power Consumption | Power consumption is less than 60 mA on average at a 60 bubble/min rate with averaged samples over 10 seconds. |

Communications |

|

| Output Options | SDI-12, RS-485 |

| SDI-12 Protocol | SDI-12 V1.4 compliant |

| SDI-12 Default "M" Measurement Response Time | 8 s |

| RS-485 Protocol | Modbus, 8 data bits, no parity, 1 stop bit |

| RS-485 Baud Rate | 9600 |

| Keypad/Display Description |

|

Videos & Tutorials

Downloads

LevelVue B10 OS v.2.2 (473 KB) 24-04-2025

Current LevelVue B10 Operating System. The Device Configuration Utility is used to send this Operating System to the LevelVue B10.

View Update HistoryFrequently Asked Questions

Number of FAQs related to LevelVue B10: 8

Expand AllCollapse All

-

No. The unit has temperature compensation on it, but it is the temperature of the sensors that will be very different from the water temperature.

-

Yes. The orifice can be installed in the well piping. Normally the orifice line is supported by a separate stainless-steel cable to prevent the orifice line from moving up or down, as this movement would show up in the data.

-

The LevelVue B10 does not log its own data and does require a data logger.

-

No. A stilling well is not needed. The orifice line is normally installed inside a two-inch conduit and secured in place, so there is no movement in the orifice line. It is best to install the outlet just above the sediment in the water to be measured. When the orifice line is securely installed, the unit makes accurate measurements of the water—even if the water has some movement, such as in a river. The measurement averaging time can also be increased to reduce the noise in the data, providing the same function that the stilling well does to average out the fluctuations of the water.

-

No. This is not a good data value for ambient air temperature. It is the temperature as seen by the internal pressure sensing element, and it will be affected by several other factors. For example, direct sunlight on an enclosure will heat it up much higher than ambient air temperature.

-

Yes. This bubbler supports the SDI-12 interface as a sensor or server, so any data logger that supports SDI-12 as a client will work.

-

Yes. This system also supports Modbus, which is supported by most PLCs.

-

The only item that requires regular maintenance is the desiccant. The interval that this needs servicing is based on the relative humidity of the site and how often the unit turns on the pump. Purging more often will draw air into the system, so that would shorten the time between visits to replace the desiccant.