For measurement of global solar radiation under changing weather conditions

Overview

The CS320 is a digital thermopile pyranometer that measures broad-spectrum short-wave radiation and communicates over the simple SDI-12 protocol to the data logger. This sensor design eliminates measurement error and programming errors that can adversely affect data quality.

This pyranometer has been designed to improve the global solar radiation measurement significantly (even under cloudy conditions) without adding substantial cost. The CS320 is suitable for applications ranging from environmental research to agriculture to large mesoscale weather networks (mesonets).

The CS320 is manufactured using a high-grade anodized aluminum body and IP68-rated 316 stainless-steel M8 connector (marine grade). The CS320 sensor is heated (on/off switchable under user control) and allows continuous operation in changing environmental conditions. The pyranometer's calibration data is stored on the sensor.

Read MoreBenefits and Features

- Thermopile sensor eliminates spectral errors associated with silicon-cell pyranometers

- Much lower price point than other thermopile sensors

- On-board sensor automatically detects if the CS320 is level for installation, diagnostics, and remote troubleshooting

- Designed for long-term stability and deployment

- Dome-shape sensor head allows dew and rain runoff

- Internal heater to reduce errors from dew, frost, rain, and snow

- SDI-12 digital output

- Detachable waterproof connector from sensor head for fast, easy servicing

- Calibration data stored on sensor

Images

Similar Products

Detailed Description

The CS320 combines a blackbody thermopile detector with an acrylic diffuser. This design is a significant improvement when compared with the spectral response of silicon photocell pyranometers, while offering a comparable price. Thermopile pyranometers use a series of thermoelectric junctions (multiple junctions of two dissimilar metals following the thermocouple principle) to provide a signal of several µV/W/m2 proportional to the temperature difference between a black absorbing surface and a reference. The thermopile pyranometer’s black surface uniformly absorbs solar radiation across the solar spectrum.

The 0.2 W heater keeps water (liquid and frozen) off the sensor to minimize errors caused by dew, frost, rain, and snow blocking the radiation path. Dew and rain runoff is faciliated by the dome-shaped sensor head (diffuser and body). This keeps the sensor clean and minimizes errors caused by dust blocking the radiation path. The sensor is housed in a rugged anodize aluminum body, and the electronics are fully potted.

The CS320 pyranometer has sensor-specific calibration coefficients determined during the custom calibration process. Coefficients are programmed into the microcontrollers at the factory. The CS320 has an SDI-12 output (SDI-12 version 1.4), where short-wave radiation (W/m2) is returned in digital format. Measurement of the CS320 pyranometer requires a measurement device with SDI-12 functionality that includes the M or C command.

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Dataloggers

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR300 (retired) | ||

| CR3000 (retired) | ||

| CR350 | ||

| CR6 | ||

| CR800 (retired) | ||

| CR850 (retired) |

Additional Compatibility Information

Measurement of the CS320 pyranometer requires a measurement device with SDI-12 functionality that includes the M or C command, as an analog version of the CS320 is not offered.

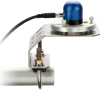

Mounting

Accurate measurements require the sensor to be leveled using a 18356 leveling fixture. This leveling fixture incorporates a bubble level and three leveling screws. The 18356 mounts to a crossarm using the CM225 mounting stand. The CS320 should be mounted away from all obstructions and reflective surfaces that might adversely effect the measurement.

Specifications

| Sensor | Thermopile detector, acrylic diffuser, heater, and signal processing circuitry mounted in an aluminum housing |

| Measurement Description | Measures broad-spectrum short-wave radiation |

| ISO Classification | Class C (second class) |

| Calibration Uncertainty | ± 2.6% |

| Measurement Range | 0 to 2000 W/m2 (net short-wave irradiance) |

| Measurement Repeatability | < 1% |

| Long-Term Drift | < 2% (per year) |

| Non-Linearity | < 1% |

| Sensitivity | 0.057 mV/W/m2 |

| Detector Type | Blackbody thermopile |

| SDI-12 Response Time | 2 s |

| Field of View (FOV) | 180° |

| Spectral Range | 385 to 2105 nm (50% points) |

| Directional (Cosine) Response | < ±20 W/m2 (at 80° solar zenith) |

| Temperature Response | < 5% (from -15° to +45°C) |

| Output | SDI-12 (version 1.4) 1200 bps |

| Zero Offset A | 8 W/m2 |

| Zero Offset B | < 5 W/m2 |

| Operating Temperature Range | -50° to +60°C |

| Operating Environment | 0 to 100% relative humidity |

| Heater | 0.2 W (on-board) |

| Heater Power Requirements | 25 mA current drain (at 12 Vdc) |

| Input Voltage Requirements | 6 to 24 Vdc |

| Current Drain |

|

| Uncertainty in Daily Total | < 5% |

| Error Due to Clouds | ±2 % |

| Mechanical Rating | IP66/68 |

| Factory Calibrations | Traceable to secondary standard blackbody thermopile pyranometers traceable to the world radiation reference in Davos, Switzerland. |

| Compliance with Standards |

|

| Warranty | 4 years against defects in materials and workmanship |

| Diameter | 3.43 cm (1.35 in.) |

| Height | 3.96 cm (1.56 in.) |

| Weight |

~65 g (2.3oz) May vary due to potting. |

Downloads

CS320 Program Example (3 KB) 11-08-2021

Two example programs that use the M4! command to return solar radiation (W/m^2), raw millivolt value (mV), sensor temperature (°C), and Z-axis values (°). The programs also calculate the daily total flux (MJ). One example program also controls the heater based on air temperature measurements, dewpoint calculations, and battery voltage measurements. The HygroVue™10 Air Temperature and Relative Humidity Probe provides the measurements used in the dewpoint calculation.

Frequently Asked Questions

Number of FAQs related to CS320: 8

Expand AllCollapse All

-

For maximum accuracy, Campbell Scientific generally recommends that all sensors be recalibrated every two years. Depending on the requirements of the application, it may be desirable to wait longer between recalibration cycles. To determine if recalibration is necessary for pyranometers, visit the Clear Sky Calculator web page.

For additional information, read the "How to Check the Accuracy of Your Solar Radiation Measurements" blog article.

-

No. It’s not the range that makes a sensor a quantum sensor. It is the type of light filter used with the photocell that only allows specific wavelengths of light in the PAR frequency range to strike the photocell.

-

The SDI-12 bus is capable of having at least 10 sensors connected to it, each with 200 feet of cable. With fewer sensors, longer cable lengths are possible.

-

Compare the sensor against a recently calibrated CS320 on a clear, sunny day with the sun overhead. Ensure that the sensor being used as a reference is also level.

-

The leveling base provides physical stability and helps ensure the sensor is leveled correctly. It is not recommended to use the sensor without the base. The sensor mounts to the base with an included bolt. However, a user-supplied plate with a hole drilled in it could be used instead to accept the sensor’s mounting bolt.

Note: Whatever mounting method is used, the sensor has to be levelled to operate correctly.

-

For thermopile pyranometers, a thermopile is used within the instrument as the sensor, and the thermal gradients are measured across hot and cold areas (black and white). The radiation intensity is proportional to the temperature differences between the two sensing areas. Accuracy depends upon the sensitivity of the material used in the sensors, the response time, and the distortion characteristics of the material constituting the dome (if present) covering the sensors.

For silicon photocell pyranometers, electric current is generated by a photo-sensitive diode in proportion to solar intensity. Ordinarily, silicon photocell pyranometers are not fully sensitive to the full spectrum of visible light, and they cannot “see” a certain portion of the electromagnetic spectrum such as under cloudy conditions or vegetative canopies. Silicon photocell pyranometers will introduce errors under these conditions. In full sunlight conditions, however, they are calibrated to properly output solar radiation measurements.

-

Whenever possible, purchase a sensor with the desired cable length. Some sensors have a user-specified cable length, whereas other sensors have a set cable length.

Sometimes, an old cable can be replaced with a new, longer cable.

Generally, additional cable cannot be spliced onto the existing cable because:

- Some sensor cables have bridge completion resistors at the pigtail end

- Some sensors are calibrated based on cable length

- Sometimes the color in the insulation is not the same as that visible at the pigtail end

- It is possible to introduce errors or malfunctions depending on the integrity of the splice

Splicing cable together increases the likelihood that water may enter the cable and cause shorting, corrosion, and some other potential issues, which in turn can cause measurement issues.

Because of the potential issues, do not splice any sensor cable without first contacting Campbell Scientific to discuss the sensor in detail.